Box Two Oversized 30mm Bottom Bracket

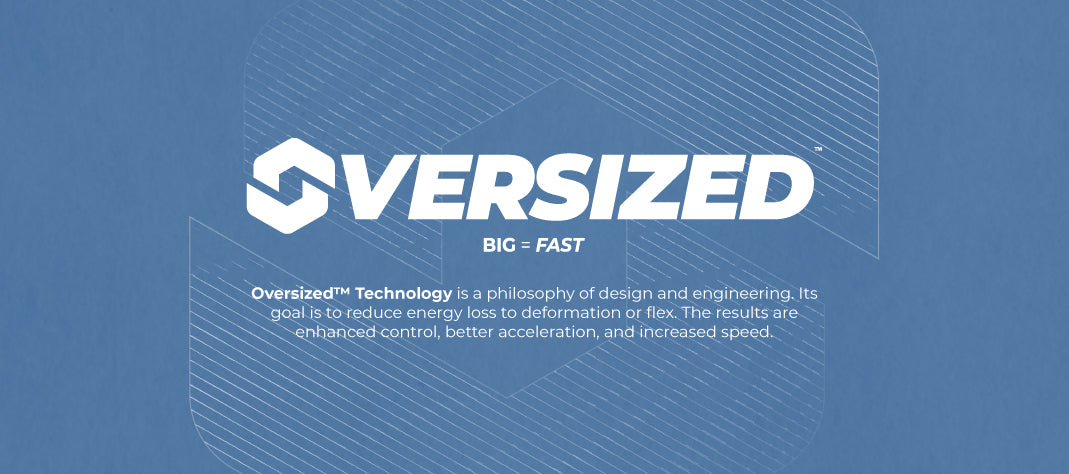

Several of the upper tier Box bottom brackets were engineered using our Oversized Technology. These were developed in concert with our crank sets. We all know that there is no use pushing hard on your pedals if you can’t deliver most of that power to the rear wheel. During the creation of our bottom brackets we were obsessed with Power delivery AKA pedaling stiffness. To reduce lateral deflection we chose to oversize the bottom bracket and therefore subsequently enlarged the spindle and the crank arm’s interfaces. This made room for larger bearing rings contributing to a vast increase in contact area. We robbed material from unloaded sections to reinforce the zones of high stress. Not only are you going to be more efficient with power delivery, but you’ll also feel the instant response of acceleration. Seen through another lens, less energy will be required to achieve the same elapsed time.

Key differences: The Box Two M30 bottom bracket is a slightly less acute embodiment of our Oversized technology seen in the M35. Generously sized ABEC-5 bearings help reduce power loss to defection. The larger 30mm cross section is designed to mate up with the rest of the M30 line of Oversized crank sets.

SKUBX-BB1730BX1-BK

Enhanced Power Delivery // FASTER

There is no use pushing hard on your pedals if you can’t deliver most of that power to the rear wheel.

Power delivery AKA pedaling stiffness. When a rider pushes down on a pedal, the pedal, crank set, bottom bracket, frame and all the hardware holding those together deflects laterally. Stiffer components deflect less, so more of your energy output goes into turning the rear wheel, rather than deforming the components and frame. By using Oversized technology, Box is able to add only the appropriate amount of material for stiffness where it is most needed. It is possible to add too much stiffness where the rider will not feel the benefits. Going beyond that point simply adds material which is surplus weight.

Superior Control // FASTER RESPONSE

Wonder why there is lag time between input from your hands to reaction from your bike?

Bike control can be defined as steering stiffness and this affects how your bike handles as a result of rider input. At Box we define steering stiffness by how much the grips, handlebar, stem, fork, wheels, frame and all hardware between twists when they are ridden around a corner. Higher steering stiffness contributes to a more responsive handling bike by reducing latency between hand input and reaction in the bike. Just as with power delivery, by using Oversized technology, Box is able to add only the appropriate amount of material for steering stiffness where it is most needed. This allows our components to combat the cornering load as it passes along its load path from grip all the way through to contact point on the track.

Armored Build // MORE DURABLE

Why invest in cutting edge components if they don’t last?

Toughness is a natural byproduct of our Oversized technology. By adding size to specific areas of components we have not only increased pedaling and steering stiffness, we have also added toughness and strength. Larger surfaces also increase the ability of a component's ability to spread impact loads.

Advanced Materials // ALL ABOVE

Not all things are equal when it comes to materials of construction.

We don’t just manufacture carbon fiber parts. We engineer where the strength/stiffness needs to be and the layer of fibers are added and aligned in the direction and angle required to provide the best effect. With metal alloys we don’t just buy “aerospace grade alloys” we choose the appropriate aluminum alloy for the component, and send it through the appropriate heat treatment processes. We demand material certifications as part of our quality assurance program.